Last updated on 2025-07-10

Program overview

The Mechanical Technician – CNC Programming (MTCP) is a two-year diploma program designed to introduce students to modern manufacturing techniques, including programming and Computer Assisted Manufacturing (CAM). This program emphasizes both theoretical knowledge and practical skills in metal machining and cutting, focusing on programming, advanced manufacturing techniques, and interpreting engineering drawings. Graduates will be well-prepared to begin apprenticeships as general machinists, tool and die makers, or mould makers, and can expect to find employment in various sectors of the manufacturing industry.

Program structure

The Mechanical Technician – CNC Programming program is structured as follows:

- Program Length: 4 Semesters (2 Years)

- Delivery Format: Hybrid, combining online and in-person learning

- Work Term Option: Optional work term available for hands-on experience

- Start Dates: Available in January and September

This program is designed to provide students with a comprehensive understanding of CNC programming and modern manufacturing techniques. The optional work term allows students to gain valuable experience in the field, enhancing their employability upon graduation. Students can choose to transfer to the non-work term stream at any time, ensuring flexibility in their educational journey.

Featured Experiences

- Hands-on Experience: Students will gain practical skills in a state-of-the-art CNC Lab.

- Work Term Option: An optional work term provides real-world experience and the opportunity to apply classroom knowledge in a professional setting.

- Career Support: Access to career coaching, networking opportunities, and a job board through Seneca Works.

- Flexible Learning: Courses are offered in a hybrid format, allowing for both online and in-person learning experiences.

Career Options

Graduates of the Mechanical Technician – CNC Programming program can pursue various career paths in Canada, including:

- Computer Numerical Control Operator: Operates CNC machines to produce precision parts and tools.

- CNC Programmer: Develops and writes programs for CNC machines to automate manufacturing processes.

- CNC Setup Technician: Prepares and sets up CNC machines for production runs, ensuring they operate efficiently.

- Quality Assurance Inspector: Inspects and tests products to ensure they meet quality standards and specifications.

- CNC Service Technician: Provides maintenance and repair services for CNC machinery, ensuring optimal performance.

- Machine Maintenance Specialist: Responsible for the upkeep and repair of manufacturing equipment.

- Technical Sales Specialist: Works with clients to provide technical support and sell CNC machinery and services.

DISCLAIMER: The information above is subject to change. For the latest updates, please contact LOA Portal's advisors.

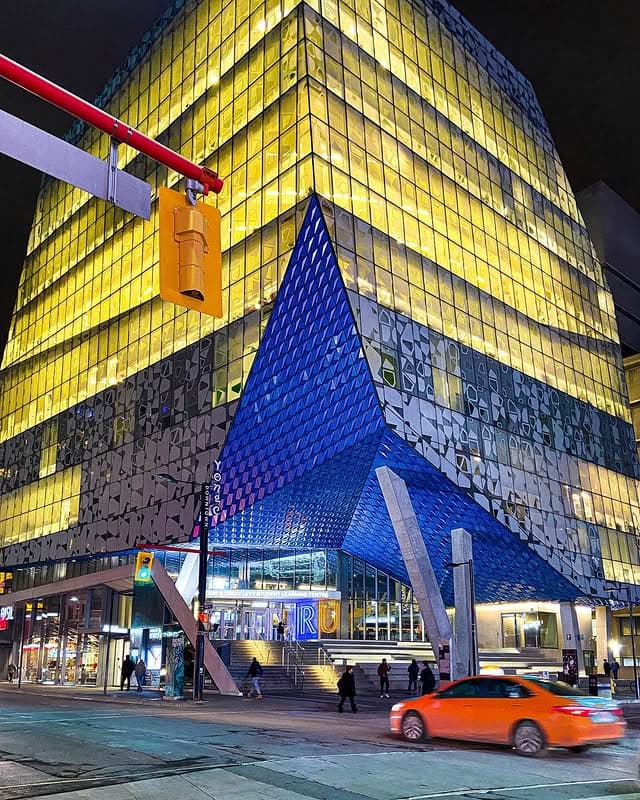

Visit Seneca Polytechnic official website