Last updated on 2025-06-24

Program Overview

The Mechanical Technician – CNC and Precision Machining program is designed to immerse students in the world of precision machining and advanced computer-controlled machine technology (CNC). This two-year diploma program combines theoretical knowledge with practical skills, providing students with hands-on training in state-of-the-art labs, including Precision Machining, CAD/CAM, CNC, Research, and Robotics. Students will learn to design and manufacture tools, jigs, fixtures, and prototypes using cutting-edge technology, preparing them for a successful career in the mechanical engineering field.

Program Structure

The Mechanical Technician – CNC and Precision Machining program spans a duration of 2 years, consisting of 4 semesters and a mandatory co-op term. The program structure includes:

- Full-time study format

- 15-week mandatory co-op placement in Year 2

- Starting months: January and September

This program is designed to equip students with a blend of advanced machine-tool technology principles and extensive hands-on manufacturing practices. Students will also receive training in mathematics, communications, and general education, enhancing their technical skills and preparing them for the challenges of the workplace.

Featured Experiences

- Hands-on training in state-of-the-art labs, including Precision Machining, CAD/CAM, CNC, Research, and Robotics.

- Mandatory 15-week co-op term in Year 2, providing real-world experience with industry partners.

- Opportunities to design and fabricate prototypes using digital manufacturing technology, such as laser cutters and 3D printers.

Career Options

Graduates of the Mechanical Technician – CNC and Precision Machining program can pursue various career opportunities in Canada, including:

- Aerospace Technician: Work on the design and manufacturing of aircraft components and systems.

- Tool and Die Maker: Create precision tools, dies, and fixtures used in manufacturing processes.

- CNC Machinist: Operate and program CNC machines to produce high-precision parts.

- Manufacturing Engineer: Oversee production processes and improve manufacturing efficiency.

- Quality Control Inspector: Ensure that products meet quality standards and specifications.

These roles are essential in various industries, including aerospace, automotive, healthcare, and construction, providing graduates with a solid foundation for a successful career.

DISCLAIMER: The information above is subject to change. For the latest updates, please contact LOA Portal's advisors.

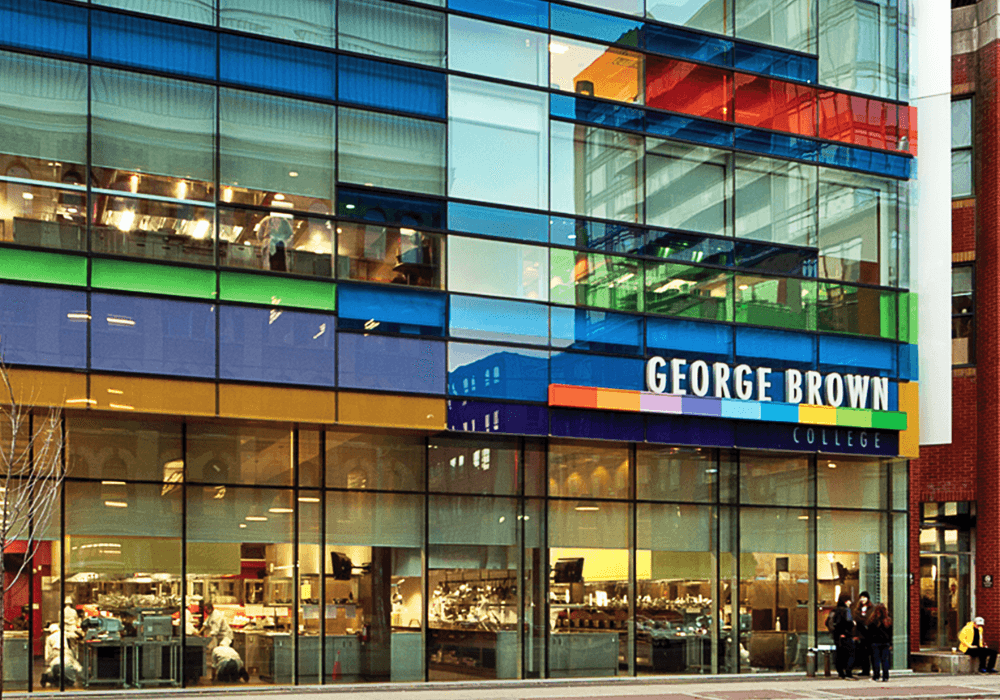

Visit GBC - George Brown College official website