Last updated on 2025-05-14

Program Overview

The Bachelor of Science in Materials Engineering Co-operative program at the University of Alberta is designed for students interested in the production, processing, and manufacturing of materials. This program emphasizes the interrelationships between structure, properties, processing, and performance of materials. As the only university in western Canada offering this program, graduates are highly sought after in various industries, including energy, biology, medicine, consumer products, and communications. The program not only equips students with essential knowledge but also prepares them for a successful career in materials engineering.

Program Structure

The Bachelor of Science in Materials Engineering Co-operative program is structured to provide a comprehensive education over a period of five years. This includes:

- Eight terms of full-time study.

- Five work terms lasting four months each through the Co-op program.

Students will have the opportunity to engage in hands-on experiences, participate in research, and work on team projects both inside and outside the classroom. The Co-op option allows students to gain relevant work experience and make valuable industry connections before graduation. The program is recognized for its strong ties to the energy and resources industries in western Canada, enhancing work placement opportunities for students.

Featured Experiences

- Co-op program offering paid, supervised work terms.

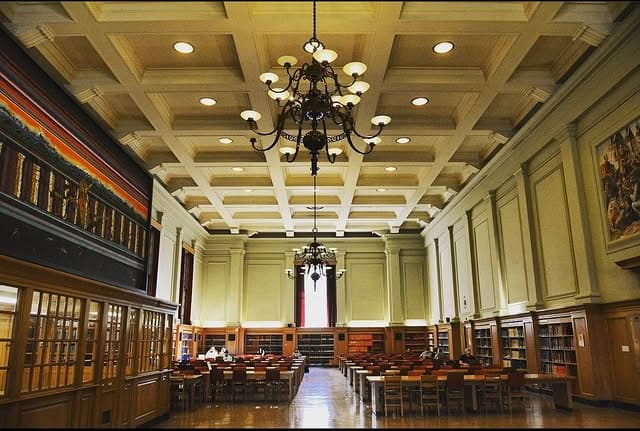

- Hands-on experience in state-of-the-art labs and teaching spaces.

- Opportunities to participate in research projects.

- Strong connections to industry, providing unmatched work placement opportunities.

- Access to specialized facilities and areas of research within the Faculty of Engineering.

Career Options

Graduates of the Bachelor of Science in Materials Engineering Co-operative program can pursue various career paths in Canada, including:

- Composites Engineer: Focuses on developing and testing composite materials for various applications.

- Corrosion Engineer: Specializes in preventing and managing corrosion in materials and structures.

- Failure Analysis Engineer: Investigates material failures to improve product reliability and safety.

- Forensic Engineer: Applies engineering principles to investigate accidents and failures in materials.

- Materials Engineer: Works on the design and development of new materials and processes.

- Nondestructive Testing Engineer: Uses techniques to evaluate materials without causing damage.

- Plastics Engineer: Focuses on the design and production of plastic materials and products.

- Quality Control Engineer: Ensures that materials and products meet quality standards.

- R&D Engineer: Engages in research and development of new materials and technologies.

- Welding Engineer: Specializes in welding processes and techniques for various materials.

DISCLAIMER: The information above is subject to change. For the latest updates, please contact LOA Portal's advisors.

Visit University of Alberta official website