Last updated on 2026-02-02

Program overview

The Welding Engineering Technology - Inspection program is a dynamic three-year advanced diploma that prepares students for the rewarding field of welding inspection and quality assurance. This program combines theoretical knowledge with practical skills in a state-of-the-art facility, focusing on areas such as welding engineering technology, metal fabrication, and non-destructive testing. Graduates are eligible to apply for certification as a Level 1 Welding Inspector under CSA W178.2 and can pursue further certification as a Certified Engineering Technologist (CET) through OACETT. The program also aligns with the learning outcomes for Level 1 of the Welder and Metal Fabricator - Fitter apprenticeship programs in Ontario.

Program structure

The Welding Engineering Technology - Inspection program is structured to provide a comprehensive education over a period of three years. The program includes:

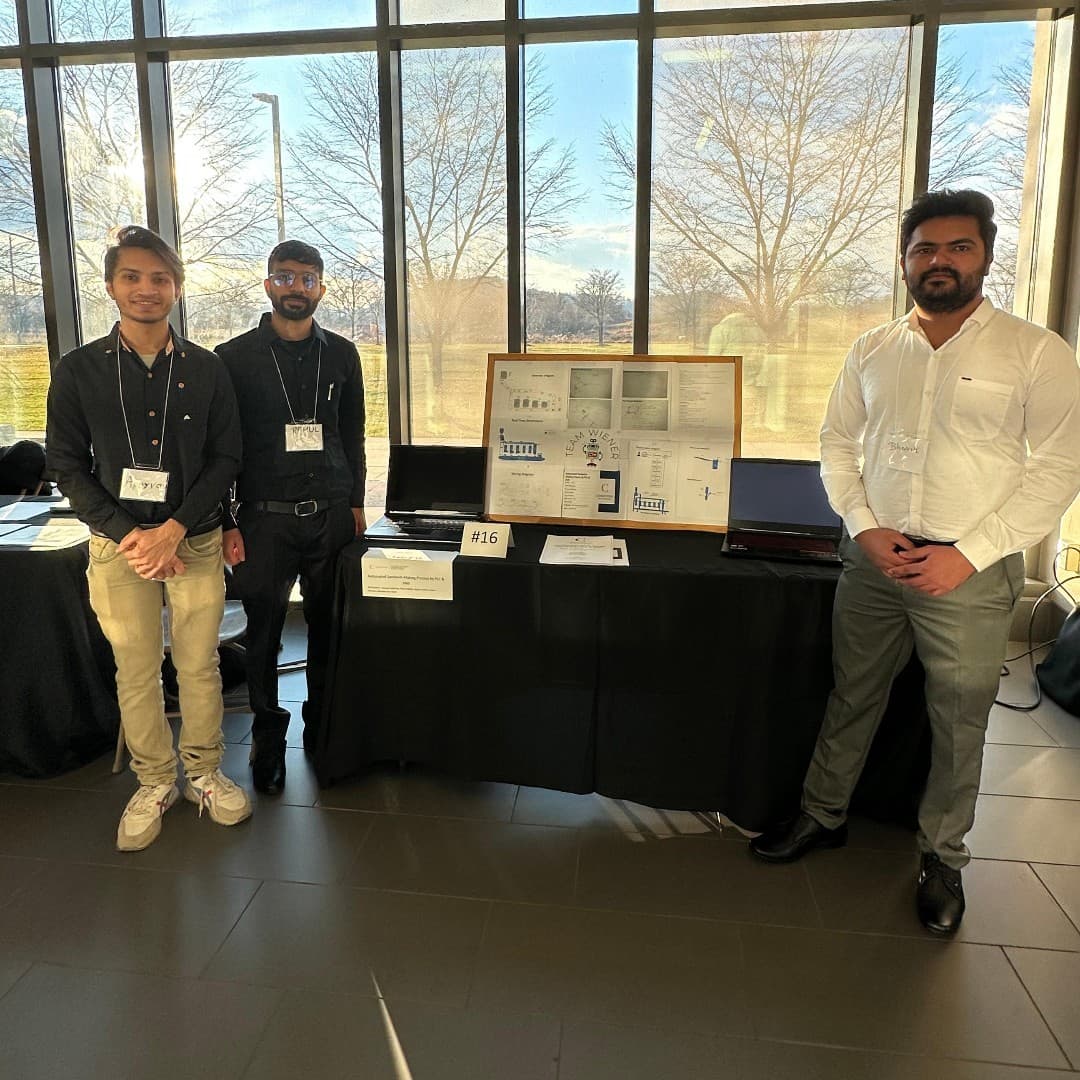

- Hands-on learning experiences in various laboratories, including welding, robotics, and metallurgical labs.

- Optional co-op stream featuring four consecutive four-month co-op work terms, allowing students to gain real-world experience.

- A hybrid delivery method, combining in-class instruction with practical applications.

This program is designed to equip students with the necessary skills and knowledge to excel in the welding industry, ensuring they are well-prepared for their future careers.

Featured Experiences

- Hands-on training in state-of-the-art facilities, providing practical experience in welding and inspection.

- Access to advanced laboratories for non-destructive testing and metal fabrication.

- Optional co-op program that allows students to gain valuable work experience while studying.

- Eligibility for certification as a Level 1 Welding Inspector upon graduation.

- Recognition by the Ontario Association of Certified Engineering Technicians and Technologists (OACETT) for meeting academic requirements for CET certification.

Career Options

- Welding Inspector: Responsible for ensuring that welding processes meet industry standards and regulations, conducting inspections and tests on welds.

- Quality Assurance Technician: Focuses on maintaining quality standards in manufacturing processes, identifying defects, and implementing corrective actions.

- Welding Engineer: Involved in the design and development of welding processes, materials, and equipment, ensuring efficiency and safety.

- Metallurgical Technician: Works with materials to analyze their properties and performance, assisting in the development of new materials.

- Robotics Technician: Specializes in the programming and maintenance of robotic systems used in welding and manufacturing processes.

DISCLAIMER: The information above is subject to change. For the latest updates, please contact LOA Portal's advisors.

Visit Conestoga College official website